Revolutionizing Industrial Heating: NIIFT’s Blueprint for Ecologically Sound Future

Introduction: Pioneering Tomorrow with NIIFT’s Steam Boilers

In the ever-evolving arena of industrial thermoregulation, NIIFT emerges as a paragon of sustainability and proficiency with its avant-garde commercial steam boilers. Tailored for the morrow, these contrivances meld the latest technological advancements to cater to the progressive needs of industries across Thailand and Southeast Asia, presenting top-tier steam boiler systems. This discourse delineates the distinctive attributes and technological advancements that position NIIFT as a vanguard in the steam boiler domain.

What Distinguishes NIIFT’s Revolutionary Commercial Steam Boilers?

Modular Configuration for Versatility

NIIFT’s steam boilers are conceived with a modular framework, providing supreme versatility in both installation and functionality. This methodology facilitates scalable solutions that can be customized to meet particular industrial requisites, significantly boosting system efficacy and flexibility—a critical element for processes that depend on industrial boilers.

Remote Surveillance for Augmented Efficiency

Armed with state-of-the-art remote surveillance technology, NIIFT’s boilers enable real-time governance of boiler activities. This functionality ensures peak performance and efficacy by permitting precise modifications and proactive diagnostics within the boiler system, markedly curtailing operational interruptions.

Emission Mitigation for Ecological Operations

At the heart of NIIFT’s design ethos is sustainability, particularly evident in the crafting of their steam boiler systems. These boilers are equipped with refined emission mitigation technologies that reduce ecological impact, aligning with both global and local environmental mandates for a more verdant future.

How Does NIIFT Maximize Energy Efficiency in Their Steam Boilers?

Cutting-edge Combustion Techniques

Central to NIIFT’s steam boilers is a pioneering combustion methodology that optimizes energy utilization and output from each quantum of fuel expended. This technique ensures the boilers operate with optimal efficiency, diminishing both operational expenses and ecological footprint—essential traits for contemporary industrial boiler systems.

High-efficiency Heat Exchangers for Supreme Heat Transfer

NIIFT employs high-efficiency heat exchangers that bolster heat transfer while minimizing energy dissipation within their boiler systems. These components play a pivotal role in preserving the efficacy of the steam generation process, ensuring maximum energy availability for industrial application.

What Elevates NIIFT’s Commercial Steam Boilers in the Industrial Sector?

Automation Integration for Streamlined Processes

NIIFT’s steam boilers incorporate automation systems that streamline operations, from fuel management to emissions regulation, elevating the overall boiler system. This integration not only simplifies the control of boiler operations but also boosts safety and reliability.

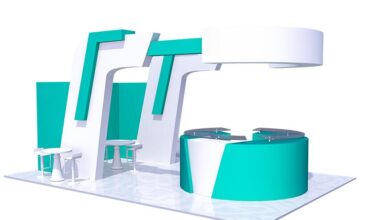

Compact Structure and Modular Build for Spatial Efficiency

The compact stature and modular architecture of NIIFT’s boilers make them ideal for industries where space is scarce. This design permits straightforward integration into pre-existing setups without the necessity for extensive site alterations.

Why is Remote Monitoring Critical in Commercial Steam Boilers?

Instantaneous Monitoring of Boiler Efficacy

Remote monitoring represents a transformative advancement for commercial steam boilers. By delivering instantaneous data on boiler efficacy, NIIFT empowers operators to make knowledgeable decisions that optimize operations and avert potential complications before they escalate Industrial Heating.

Proactive Maintenance for Enhanced Dependability

With remote monitoring, maintenance shifts from reactive to proactive. This strategy not only prolongs the boiler’s life span but also ensures it operates at peak efficiency, reducing both unscheduled downtime and maintenance expenditures.

How Does NIIFT Address Environmental Concerns with Their Steam Boilers?

NOx Emission Curtailment Techniques

NIIFT’s boilers are crafted with techniques that substantially diminish nitrogen oxide (NOx) emissions, a notable contributor to atmospheric pollution. This technology is crucial for complying with stringent environmental standards and safeguarding community health, particularly in the realm of industrial boilers.

Adoption of Biofuels for Ecological Heat Production

Beyond merely embracing technological innovations, NIIFT fervently advocates for the use of biofuels as a vital, sustainable energy source for steam generation in their cutting-edge industrial boiler systems. Biofuels, derived from organic materials such as plant biomass and recycled waste, stand as a significantly cleaner alternative to conventional fossil fuels. By integrating biofuels, NIIFT’s boilers can achieve combustion with considerably lower emissions of carbon dioxide, particulates, and other pollutants that contribute to environmental degradation. This shift not only substantially diminishes the ecological footprint of industrial processes but also aligns with global initiatives aimed at reducing reliance on non-renewable resources. Furthermore, the use of biofuels helps stabilize energy costs and reduce vulnerability to fluctuations in fossil fuel markets, ensuring a more predictable and sustainable operational cost for businesses relying on steam power. This strategic adoption underscores NIIFT’s commitment to advancing environmental stewardship while enhancing the sustainability of industrial heating solutions.

Conclusion: Spearheading Steam Boiler Innovations

NIIFT stands at the forefront of the steam boiler industry, propelling innovation and sustainability with each industrial boiler design. Their dedication to energy efficiency, ecological responsibility, and avant-garde technology secures their position as a leader in commercial heating solutions and industrial boiler systems in Thailand and beyond.

About NIIFT

NIIFT (National Industrial Innovations for Tomorrow) specializes in delivering premier energy solutions across Southeast Asia, with a concentrated emphasis on industrial boiler systems. Committed to innovation and sustainability, NIIFT strives to provide efficient, eco-friendly heating technologies that enable industries to flourish while conserving the envi environment.