Uncategorized

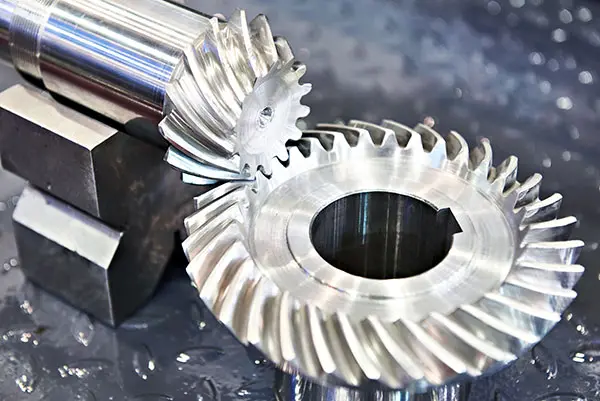

Material Selection and Heat Treatment Processes for High-Durability Spiral Bevel Gear

Material Selection for High-Durability Spiral Bevel Gear

-

Steel Alloys:

- AISI 9310: Known for high core strength and excellent fatigue resistance. It is often used in aerospace applications.

- AISI 8620: Popular for carburizing applications, providing a hard surface and a tough core.

- AISI 4140: Medium-carbon alloy steel, offers high strength, good toughness, and wear resistance.

-

Nickel-Based Alloys:

- Inconel 718: Excellent for high-temperature applications, with superb strength and oxidation resistance.

- Monel K-500: Combines excellent corrosion resistance with increased strength and hardness.

-

Titanium Alloys:

- Ti-6Al-4V: Lightweight with high strength and excellent corrosion resistance, commonly used in aerospace.

Heat Treatment Processes

-

Carburizing:

- Objective: Increase surface hardness while maintaining a tough core.

- Process: The spiral bevel gear is heated in a carbon-rich environment at 850-950°C, then quenched and tempered.

- Result: Surface hardness typically around 60 HRC, with a case depth of up to 2mm.

-

Nitriding:

- Objective: Enhance surface hardness and wear resistance without significant distortion.

- Process: The spiral bevel gear is exposed to nitrogen-rich gas at 500-550°C for an extended period.

- Result: Surface hardness around 70 HRC, with a shallow case depth of 0.3-0.6mm.

-

Induction Hardening:

- Objective: Localized hardening of specific gear areas.

- Process: The spiral bevel gear teeth are heated using an induction coil followed by rapid quenching.

- Result: Surface hardness of 50-60 HRC, with controllable depth of hardening.

-

Tempering:

- Objective: Reduce brittleness while maintaining hardness.

- Process: The spiral bevel gear is reheated to 150-200°C after quenching.

- Result: Improved toughness and resistance to impact.

-

Shot Peening:

- Objective: Improve fatigue resistance.

- Process: The spiral bevel gear surface is bombarded with small spherical media.

- Result: Induces compressive stresses on the surface, enhancing durability and fatigue life.

Combining Material Selection and Heat Treatment

- AISI 9310 with Carburizing: Ideal for high-load applications requiring a tough core and hard surface.

- AISI 8620 with Nitriding: Suitable for spiral bevel gear needing excellent wear resistance and moderate load-bearing capacity.

- AISI 4140 with Induction Hardening: Good for applications where localized hardening is sufficient, providing a balance between hardness and toughness.

- Inconel 718 with Age Hardening: For high-temperature environments, offering stability and strength at elevated temperatures.

- Ti-6Al-4V with Surface Coating: When weight reduction is crucial, often combined with surface coatings for enhanced wear resistance.

Summary

Selecting the appropriate material and heat treatment process for spiral bevel gear depends on the specific application requirements, such as load, speed, environmental conditions, and desired lifespan. By combining advanced materials with precise heat treatment techniques, high-durability spiral bevel gear can be produced to meet the most demanding performance criteria.